aluminum_wiring

Is the electrical wiring in your house safe?

Aluminum Wiring is it dangerous to have

Most likely it is but if your home was built tween approximately 1965 and 1973, aluminum wiring was often substituted for copper branch circuit wiring in residential systems. This was due to the sudden rise of the price of copper. Aluminum is a good conductor, and at the time seemed like a reasonable choice. Unfortunately homes built with aluminum wiring are 55 times more likely than those with copper wiring to overload and increase the possibility of a fire due to the inherent qualities of the metal. This risk increases every year. Last year more than 24,000 home fires were caused by faulty electrical wiring.

What to Watch For

The potential signs of electrical overheating to watch out for are:

- Flickering or dimming lights: If you notice this this could be a sign that there is a problem with electrical wiring including a loose connection from aluminum wiring or the overloading of your circuits. Every year we get more and more electrical devices which puts a larger burden on your electrical system. Having aluminum wiring makes this even worse.

- Burnt or discolored outlets: If you notice outlets that are burnt or discolored this could be a another sign of the problem with electrical wiring and should be checked. A wire to the outlet could be loose or shorted. While usually this would cause your circuit breaker refused to trip, sometimes it is just low enough not to.

- Unusual odors: If you detect a burning smell then you should immediately turn off the circuit if possible and contact an electrician. This, as always, would be a good time to remember your smoke detectors.

Aluminum Wiring Arcing

Risks

Some of the risks of aluminum wiring include:

- Overheating: Aluminum wiring is a higher rate of expansion and contraction than copper wiring which can cause the wiring to become loose over time. Loose connections can lead to overheating and arcing which can cause electrical wires

- Oxidation: aluminum wiring is more prone to oxidation than copper wiring which can cause the wiring to deteriorate over time. As it does to be more prone to overheating and fire risk.

- Flexibility: aluminum is not as ductile or flexible as copper wiring hence is easily cracked and will not give a good connection. This creates a higher resistance which can again lead to overheating.

- Incompatibility with some devices: some electrical devices such as switches and outlets are designed for use with copper wiring and may not be compatible with aluminum wiring. Using these can also increase the risk of overheating and create a fire risk

- Difficulty in repair and maintenance: repairing and maintaining aluminum wiring can be more challenging than copper wiring as it requires specialized tools and techniques. Aluminum is soft and highly sensitive to compression. After a screw has been over tightened on lumen wiring the wire will continue to deform which can cause a loose connection and increase electrical resistance in that location. If aluminum wiring is damaged or needs repaired is important to hire a qualified electrician to do the job

- Contractors: The engineers at Middle Tennessee Inspections work with some great contractors. Here is out list https://www.tenninspect.com/contractor-list/

Breaker with aluminum wiring

Is my House Unsafe?

Having aluminum wiring does not mean that the house is at a medically unsafe as there are many ways to mitigate risks associated with aluminum wiring. If your house has aluminum wiring it is recommended to have inspected by qualified electrician determined if any remedial actions are necessary.

- Installing copper pigtails: Copper pigtails can be installed at the ends of the aluminum wiring and connected to the copper wiring in the switches, outlets, and other electrical devices. This can help to reduce the risk of overheating at the connection points.

- Installing specialized connectors: There are connectors called “CopAlum crimps” that are specifically designed for use with aluminum wiring. These connectors can help to ensure a secure and safe connection between the aluminum wiring and the electrical devices but require a special tool. Anti-oxidant paste is also required.

- Replacing the aluminum wiring: In some cases, it may be recommended to replace the aluminum wiring with copper wiring. This can be a more expensive option, but it can provide greater peace of mind and reduce the risk of electrical fires.

- Make sure GFCI and AFCI up to date: As with any type of wiring make sure that you are fully protected. Even they were not required in 1973 you should make sur that you have GFCI and AFCI protection. We even have a blog – https://www.tenninspect.com/arc-fault-circuit-interrupters-afci/

It’s important to note that any remedial actions should be undertaken by a qualified electrician who has experience working with aluminum wiring. They will be able to recommend the best course of action for your specific situation, and ensure that the work is done safely and up to code.

CopAlum Connectors installed

Identifying Aluminum Wiring

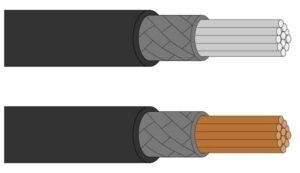

Aluminum wires are a silver-ish color and more shiny whereas copper wiring is more orange-ish. Often the word” aluminum” or the letters “AL” May be embossed or printed on the wire insulation. If your house was built between 1965 and 1973 there is a very good chance you have aluminum wiring.

Aluminum Wire Comparison

Summary

Having aluminum wiring in your home does not necessarily mean that you will have a fire, but you should be aware, check, and prepare. The inspector engineers at Middle Tennessee Inspections are InterNACHI Certified and can quickly let you know if you have aluminum wiring.

Call the engineers at Middle Tennessee Inspections today